Our Products

It does not matter whether it is a large or a small project, we will take care of it.

For more details please contact us. email: allen88@allanmachine.com

FEATURE OF TURNKEY PROJECT

EQUIPMENT FOR PRODUCTION TORTILLA CHIPS

- MASA MIXER 10 HP

- MASA FEEDER 3HP

- SHEETER 3HP X 2 (DISCHARGE CONVEYOR INCLUDED)

- TOASTING OVEN 2HP (DISCHARGE CONVEYOR INCLUDED)

- EQUILIBRATOR 2HP (DISCHARGE CONVEYOR INCLUDED)

- FRYER 10HP

- COOLING CONVEYOR 2HP

- FLAVORING TUMBLER 1/2 HP (SEASONING POWDER SPREADER INCLUDED)

- AUTOMATIC PACKAGING MACHINE SYSTEM 10HP CAPACITY: 220 POUNDS TO 1000 POUNDS PER HOUR

- CORN COOKING SOAKING SYSTEM 6HP

- CORN WASHING MACHINE 1 HP

- CORN GRINDING MACHINE 10 HP

- MASA FEEDER 3HP

- SHEETER 3HP X 2 (DISCHARGE CONVEYOR INCLUDED)

- TOASTING OVEN 2HP (DISCHARGE CONVEYOR INCLUDED)

- EQUILIBRATOR 2HP (DISCHARGE CONVEYOR INCLUDED)

- FRYER 10HP

- COOLING CONVEYOR 2HP

- FLAVORING TUMBLER 1/2 HP (SEASONING POWDER SPREADER INCLUDED)

- AUTOMATIC PACKAGING MACHINE SYSTEM 10HP CAPACITY: 220 POUNDS TO 1000 POUNDS PER HOUR

START TO USE CORN MASA FLOUR

START WITH COOKING CORN

TORTILLA CHIP | PEANUT CRACKER | NOODLE SNACK

GREEN PEA AND CORN NUT PRODUCTION LINE

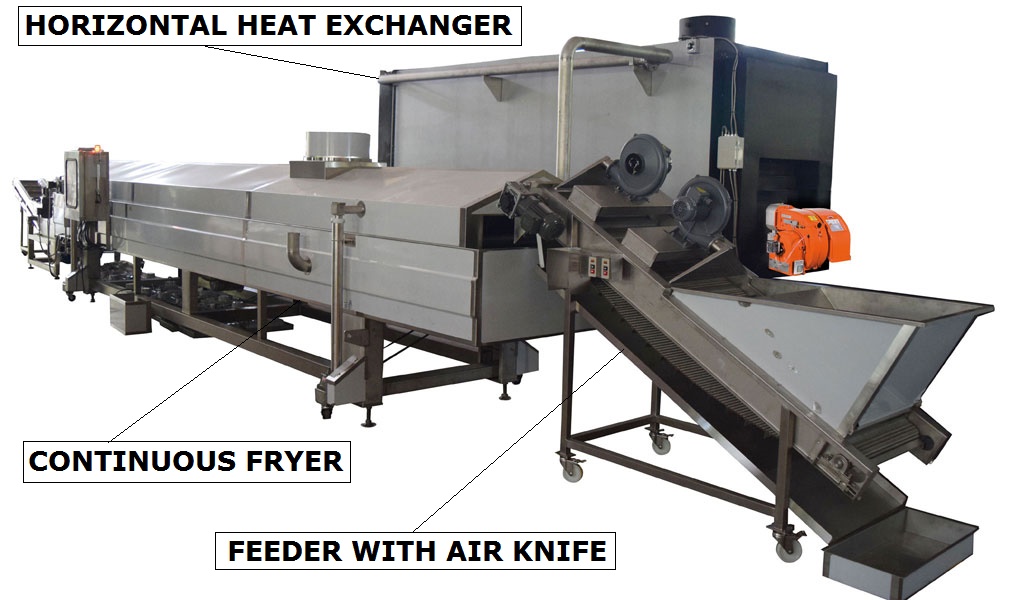

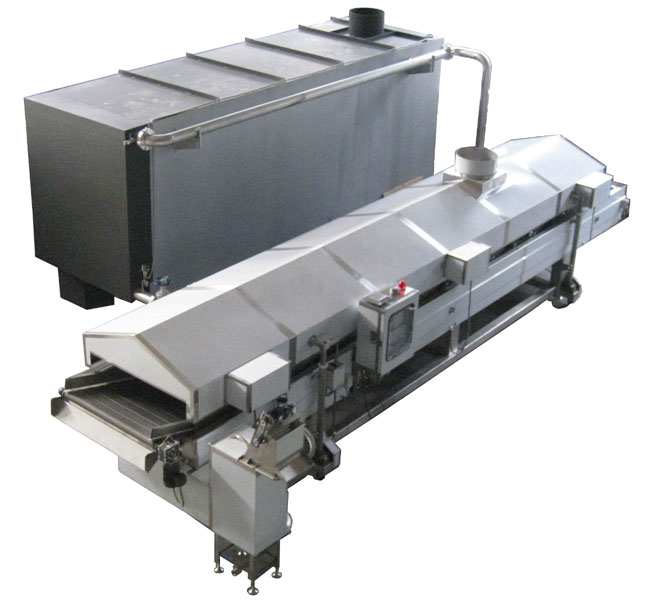

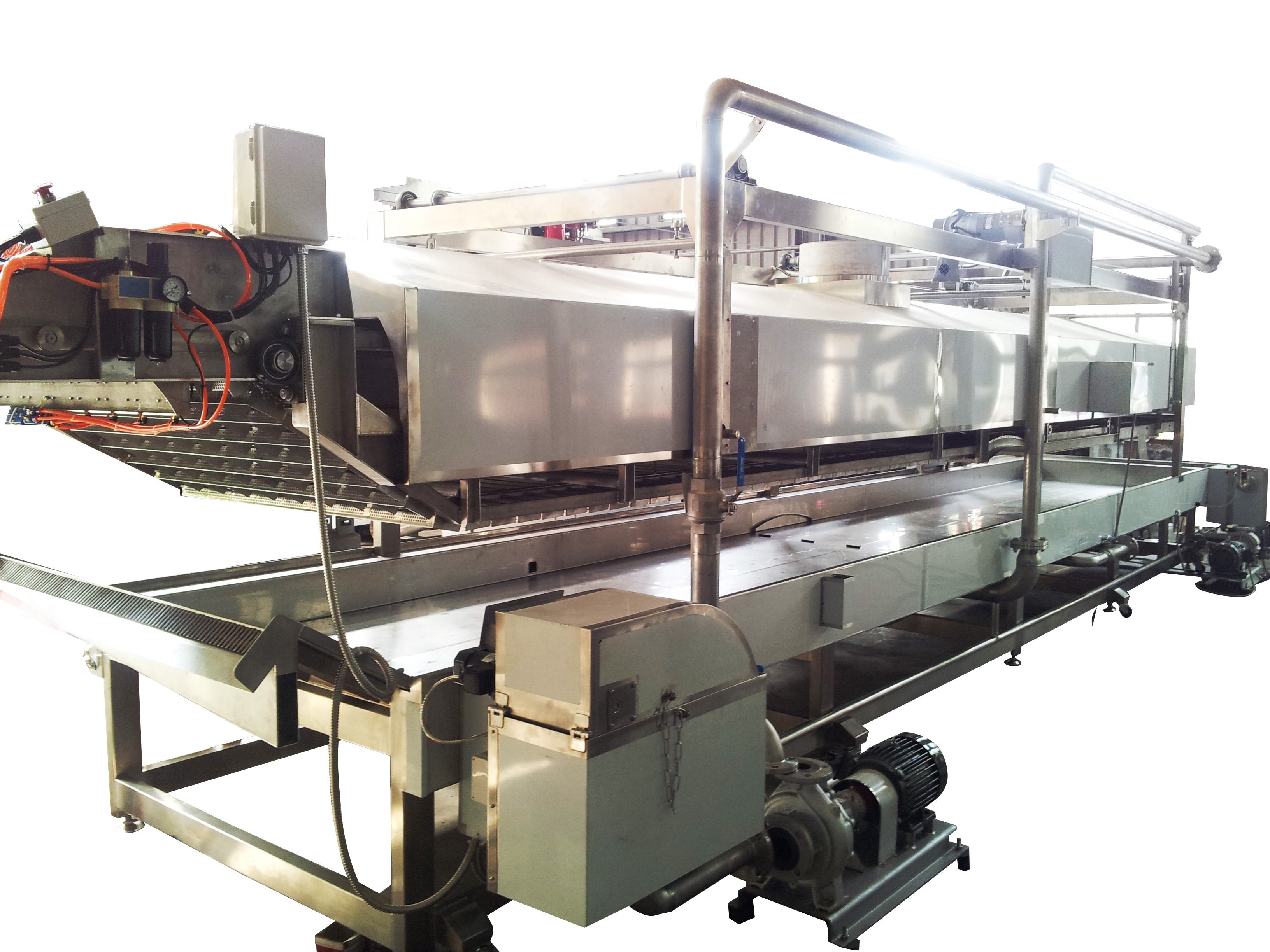

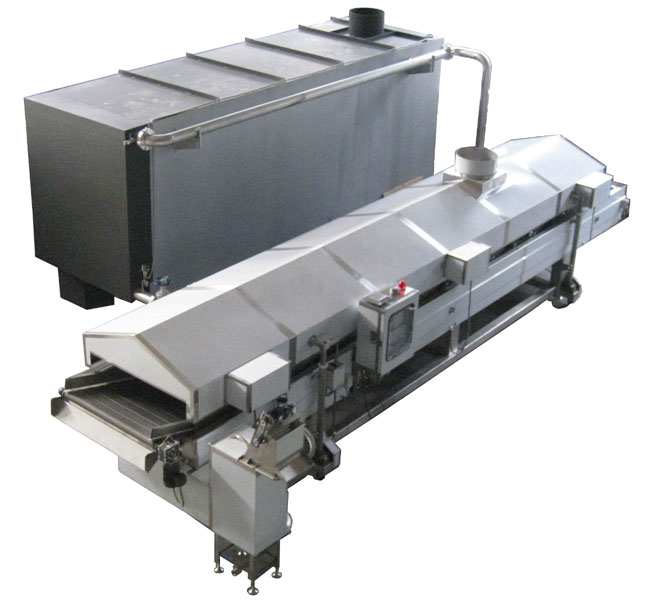

FRYER

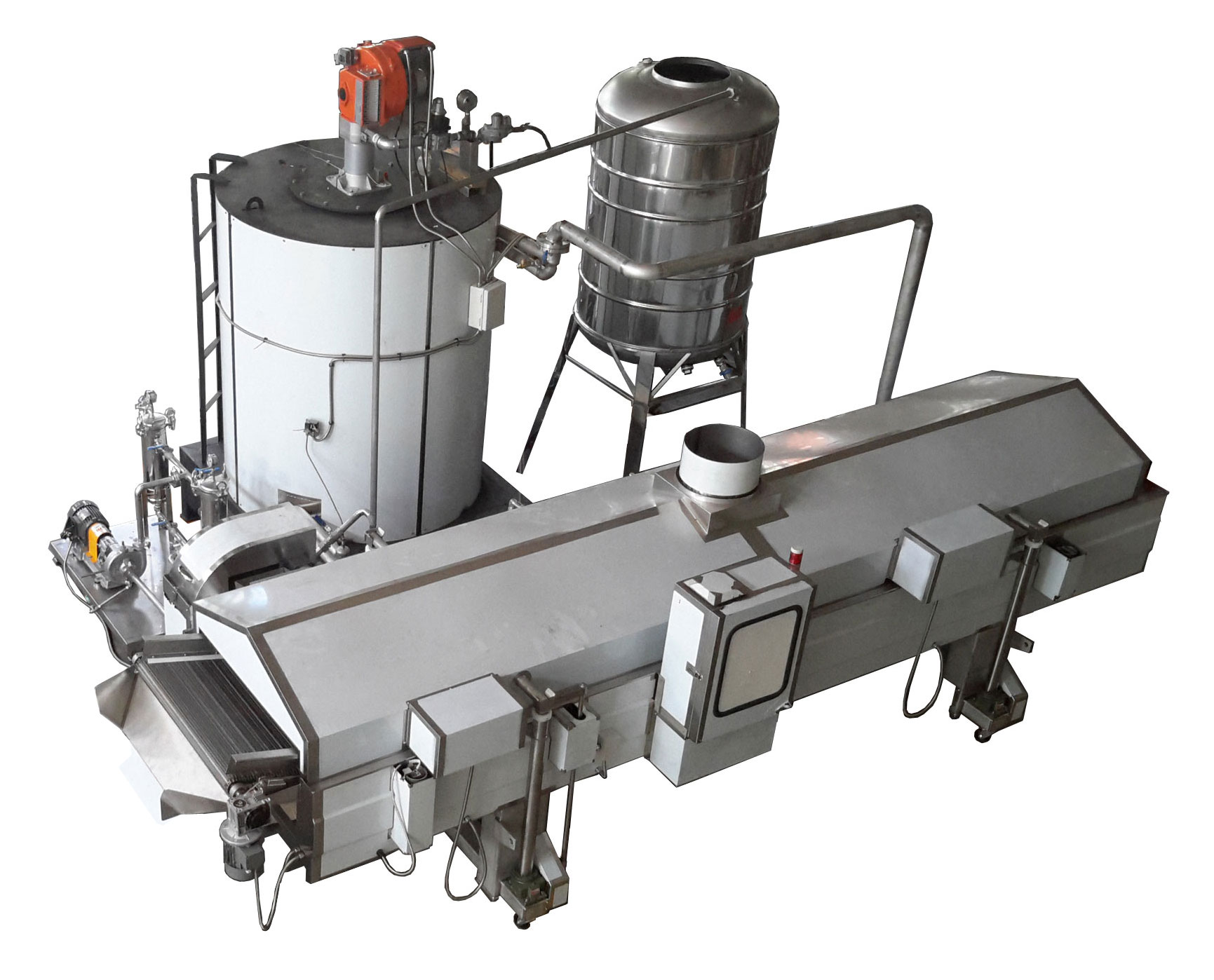

- External heat exchanger for maximum heat transfers and oil turnover.

- Conveyor system incorporating two paddles and a submerging conveyor with a variable speed drive to produce an ideal environment for frying snack products.

- Complete fryer interface with temperature controller, temperature readouts for oil inlet, and on/off controls for entire system.

- Automatic shutdown when oil inlet pressure is enough, complete warning light system.

- High horsepower oil circulation pump. Ensures constant 350°C with high longevity design and made from German.

- High oil flow, critical for proper heat transfer and proper frying.

- Combustion with flame safety system. Automatic diesel burner design and made from Japan.

- All stainless steel construction, sanitary design and make cleaning easy.

- Electric powers supply 10 Hp with a trim control panel.

FEATURE OF CORN OVEN

- 1. High production of sheeting corn tortilla chip.

- 2. Large 12.5” diameter rollers.

- 3. Uniform thickness control system.

- 4. Dual speed drives system with one 4-row cutter.

- 5. Heavy stainless steel construction, pneumatically tensioned wire.

- 6. Capacity maximum 500 lb per hour.

- 7. Electric powers supply 3 Hp for Sheeter.

- 8. One Cutter assemblies include.

- 9. High throughout and the utmost consistency.

- 10. Burn system incorporates high output burner for uniform baking.

- 11. Maintaining heat uniformity across the baking belt.

- 12. Electric powers supply 3 Hp for 3 tier Roast Oven.

FEATURE OF CORN TORTILLA SHEETER

- 1. High production of sheeting corn tortilla chip.

- 2. Large 12.5” diameter rollers.

- 3. Uniform thickness control system.

- 4. Dual speed drives system with one 4-row cutter.

- 5. Heavy stainless steel construction, pneumatically tensioned wire.

- 6. Capacity maximum 500 lb per hour.

- 7. Electric powers supply 3 Hp for Sheeter.

- 8. One Cutter assemblies include.

- 9. High throughout and the utmost consistency.

- 10. Burn system incorporates high output burner for uniform baking.

- 11. Maintaining heat uniformity across the baking belt.

- 12. Electric powers supply 3 Hp for 3 tier Roast Oven.

TORTILLA OVEN

- WJ-25WR wheat tortilla machine makes the best quality with the natural wheat aroma and flavor.

- It produces 10 pieces per minute of 10 to 25 cm diameter wheat flour tortilla.

- It is manufactured in stainless and has frames of chromium plate gates.

- It provides with fire-resisting glass. Has an automatic feeder that leads as a trolley loader.

- Provide a series of movement perfectly synchronized to make the machine more efficient.

It is designed for restaurants, self service stores, industrial dining rooms, taco shops and tourist villas.- Machine size: 110 cm length, 110 cm width and 160cm height. Weight: 450 kg. With 1 Hp motor, 220 /380 Volts, monophase or 3 phase.

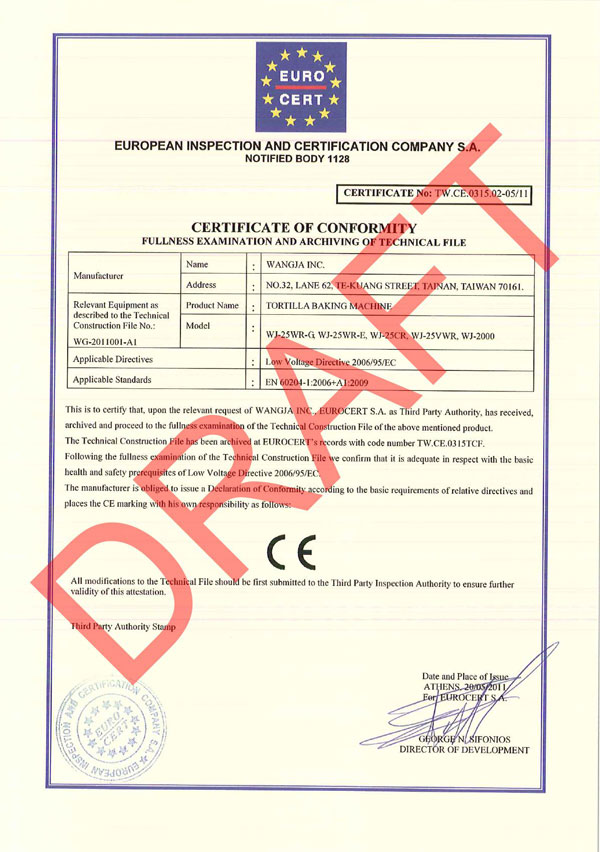

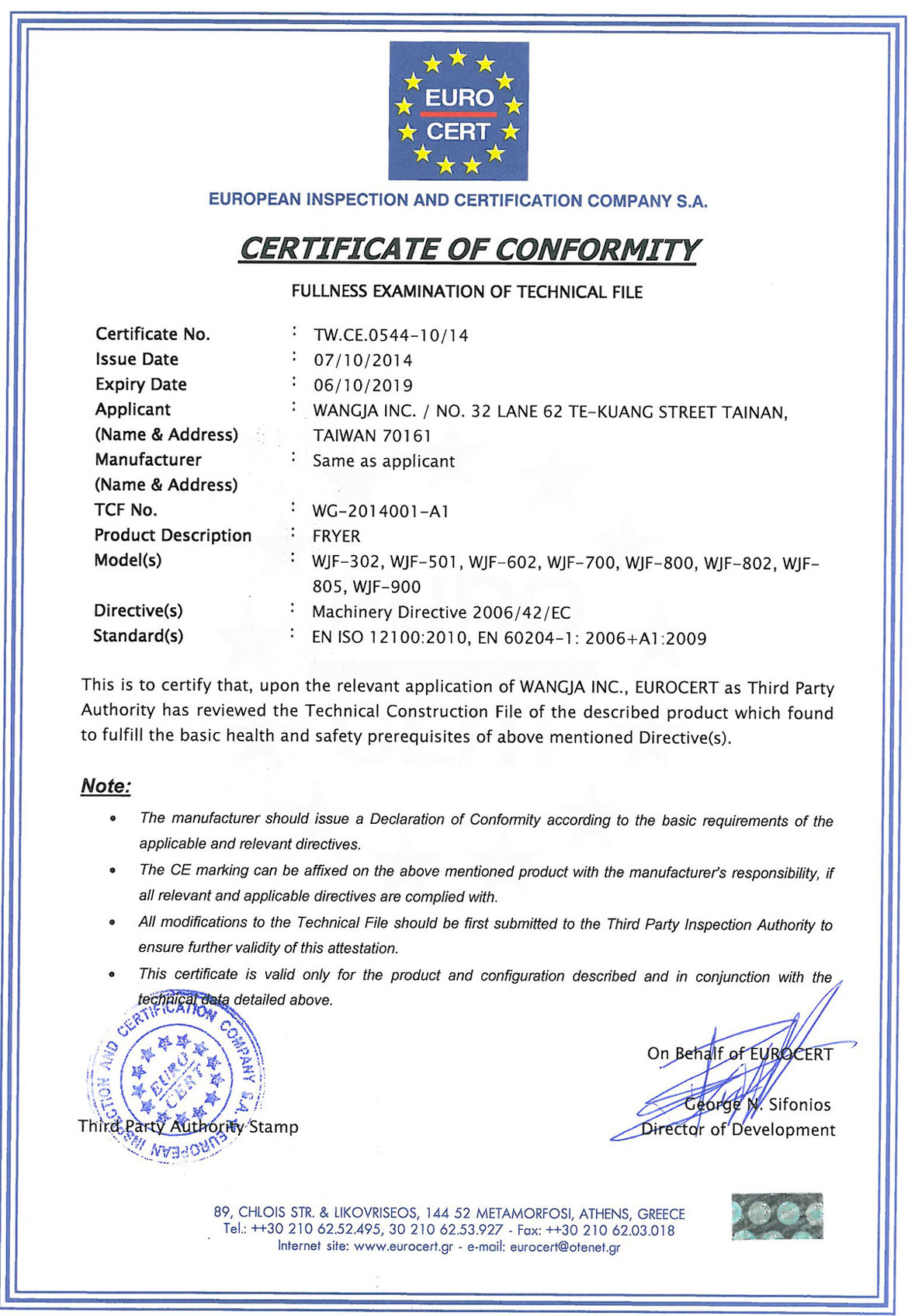

- CE CETIFICATED

FEATURE OF CONTINUOUS VIBRATION SHIFTER OVEN

- Feature of Continuous Vibration Shifter Oven

With special lagging material, needs only short time to bake out crisp & delicious roasting outcomes.- With distinguished design of double heating, quick to heat and save gas.

- Adopts gas ignition, each heater may be controlled individually, the degree of flame may be regulated at will.

- With vibrating sifter on which there are 9 cone isolation to avoid foods stick together and to secure fine & even when roasting.

- Automatic control temperature and roast time it’s easy to operate and save labor.

Low maintenance expense.- Capacity: About 200-300 kgs/Hr.

Weight: 2500kgs.

Horse power : 3HP.

LPG Gas consumption approx. : 20–30 Kg/hr

- CORN TORTILLA CHIPS PROCESSING LINE

- PEANUT CRACKER PROCESSING LINE

- GREEN PEA PROCESSING LINE

- CHEWING GUM PROCESSING LINE

- NOODLE SNACK PROCESSING LINE

TORTILLA CHIPS AND VARIOUS SNACKS FRYER

POTATO CHIPS FRYER

PEANUT CRACKER PROCESSING LINE

Japanese style Peanut Cracker, Green Pea

DESCRIPTION OF EQUIPMENTS

- PEANUT SORTER 1/2 HP

- ROAST OVEN 2 HP

- CRASHER 2 HP

- BLENDER 2 HP

- COATING PAN 2 HP

- VIBRATION SHIFT OVEN 2 HP

- SEASONING SPRAYER 1 HP

- OCTAGON COATING PAN 1 HP

- DISCHARGE CONVEYOR 1 HP

- 3 TIER DRYER 2+2 HP

- COOLING CONVEYOR 2 HP

- THIS PROCESSING LINE NOT ONLY FOR PEANUT BUT ALSO PROCESSING FOR OTHER NUTS SUCH AS CASHEW NUT, ALMOND, PISTACHIO, PUMPKIN SEED, AND SUN FLOWER SEED.

FEATURE OF BELT FILTER

- 1. Heavy-duty stainless steel construction.

- 2. Continuously remove fine particles, sediment from cooking oil.

- 3. Fine mesh metal belt, Filter net conveyor, use 250 mesh stainless net belt.

- 4. Filter area: 200 Liter per minute per square meter.

- 5. Oil level control.

- 6. Power supply: 1 HP pump X 2, Drive motor 1/2 HP, Air blow 5 HP

It does not matter whether it is a large or a small project, we will take care of it.

For more details please contact us. email: allen88@allanmachine.com