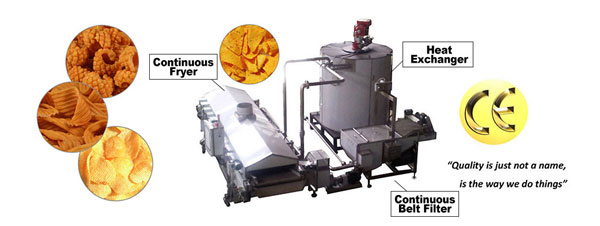

Features

- ALLAN’s unique continuous fryer designs help you produce the products of the best quality.

Features: - Continuous oil circulation through the fryer, filter and heat exchanger provides the precise control of temperature and quick adjustment while changing the amount of the products.

- Oil inlet maintains stable oil flow to clear the product in feeding area without

- creating back eddies or undercurrents.

- Fryer metering paddles and a submerge conveyor help to control cooking time for

- consistent and uniform products.

- Superior oil quality, Low oil volume and rapid oil circulation assure the freshness of the product with a long shelf life. Oil level is maintained automatically.

- Easy cleaning: Clean-in-place (CIP) spray nozzles in the hood and exhaust stack

- help clean all oil circulating areas. Circulating cleaning system circulates the cleaning water and Sodium bicarbonate following the same path as cooking oil, thoroughly cleans and sanitizes all areas.

- Self-locking motorized screw jacks raise the hood, paddles, and submerge conveyor, giving the complete access to the frying bed.

- Friendly design for easy operate and maintenance.

- Pressure switch to check frying oil pressure inside the piping.

- Emergency STOP button on both sides for safety operation.

- AII motors are provided with overload protector for safety operation.

- PLC touch panel. Use water proof control box to protect electric components.

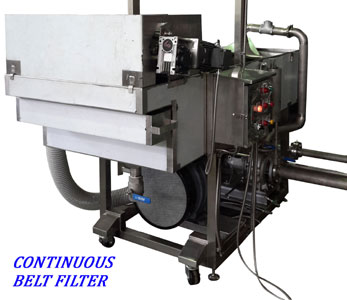

- Oil can be screened continuously, food won’t be stained.

- Automatic control to quantity of oil, together with spare of oil supplying tank.

- Conveyor can be rise and fall for easily clean.

- Special design to oil soot collecting, filthy oil will not seep through back.

- Oil temperature and flow speed can be certainly controlled.

- Frying time can be adjustment.

- Indirect heated, quality of food is stable, so food shelf-life can be extended.

- Fuel can be chosen as: diesel, heavy oil or gas.

- Automatic fire lighting, keeps detect system the oil pressure, and secure safety of operators.

- Whole machine is made by stainless steel.

- External heat exchanger energy up to 1,200,000 KCAL per hour.

Main Export Market

Europe ,Middle East ,North America ,Oceania ,South America, Asia , Africa